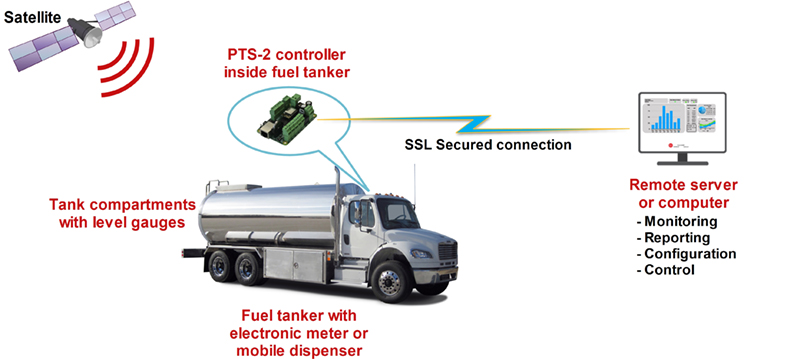

Technotrade provides automation of control over petroleum products delivery by fuel trucks using the PTS-2 forecourt controller

PROBLEM

The relevance of the task of monitoring the operation of fuel trucks when delivering petroleum products is known and obvious. It seems advisable to ensure not only control over the route of the fuel truck, but also control and protection against theft of petroleum products, control over the locations and volume of drains when fuel trucks are moving. In a more general case, when using fuel trucks as mobile filling stations, full control of such a mobile filling station is also necessary. This is especially important for fuel trucks with multi-section tanks, where it is important to record sales by various forms of payment, register receipts and releases, generate various reports, work with card systems and mobile payment applications.

SOLUTION

The PTS-2 forecourt controller developed by the Technotrade LLC company has an extremely broad functionality for for monitoring the turnover of petroleum products when they are delivered by fuel trucks or when using fuel trucks as mobile filling stations.

PTS-2 controller already supports operation with most popular brands of electronic register meters used on fuel delivery trucks including:

- Gilbarco Veeder Root EMR3 and EMR4

- Total Control Systems TCS 3000

- Liquid Controls LectroCount LCR II, LCR 600, LCR iQ

- Satam Equalis

- SAMPI TEX, TE550

- IPT

- Yokogawa Rotomass

- other brands

PTS-2 controller can be equipped with a GPS module for tracking of fuel tankers’ location:

- tracking of the present location

- tracking of the whole route covered for specified period

- tracking of the fuel level in tanks while the fuel tanker was moving on route

- tracking of places, where fuel level in tanks was changed (tank should be equipped with the probe)

- tracking of places, in which fuel was dispensed through the flowmeter

Having this information, it is possible to know present location of the fuel tanker on the route and the, most important, to know possible frauds done with fuel while the tanker is on the route because PTS-2 controller records GPS places if any change of fuel level in tank is done, PTS-2 controller automatically sends this data to a remote server for processing and analysis.

At this, PTS-2 controller automatically accounts all the dispensing performed, with saving to local database and upload to a central server. Additionally, PTS-2 controller can automatically calculate temperature-compensated volume of dispensed fuel if such option is not provided by the meter used.

If the fuel truck has tanks equipped with ATG system – then PTS-2 controller will automatically detect dispensings made from tanks and deliveries made to tanks with saving to local database and upload to a central server.

It is possible to evaluate fuel frauds or leakages done while the tanker is on the route as PTS-2 controller records GPS coordinates and controls any change with fuel levels in tank. Based on these records you can define exact location, where fuel removals or receptions happened without allowed registration.

Among many functional capabilities of the PTS-2 controller, there are some that are especially necessary when using it to automate the control of petroleum products during their delivery by fuel trucks:

- the PTS-2 controller allows to control any type of equipment installed on fuel trucks (register meters, level meters, card readers, etc.)

- the PTS-2 controller has a built-in GPS module and tracks the travelled route by the fuel delivery track and places of performed fuel; deliveries and receptions, later the reports on the travelled route can be generated as locally, so as remotely on a central server

- the PTS-2 forecourt controller provides control over possible fuel thefts of fuel from the tanks, automatically monitoring the time and place of fuel receptions and sales, generates a daily inventory of fuel receipts and releases during a specified period, using level gauges installed in the fuel tanker's tanks

- the PTS-2 controller is a full-fledged IoT device and as a normal Internet thing allows easily integration into any cloud solutions: ERP-systems, payment systems, Head-Office systems, card payment systems etc.

- the PTS-2 controller has integration with most vehicle identification systems (AVI) and allows to identify the customer's vehicles

- the PTS-2 forecourt controller is able to establish communication with a remote server itself without a need to have any static IP-address, VPN or Dynamic DNS services

- the PTS-2 controller provides remote diagnostics and technical support, monitors the operation of fuel tanker equipment (equipment malfunctions, parameters going beyond acceptable limits, equipment failure, etc.), identifies sources of malfunction, provides remote setup and remote configuration of equipment operation, which ensures fast technical support

- the PTS-2 controller provides integration with any cloud mobile applications, card solutions from various developers and other payment systems for customer service, collects a database of all transactions, provides remote visualization of reports via the Web interface

- the PTS-2 forecourt controller provides control over leakages from tanks and pipes allowing to quickly notify about it and prevent them

- the PTS-2 forecourt controller provides tanks automatic calibration with formation of tanks calibration tables based on actual fuel sales and in-tank deliveries, formation of daily inventory reports

- the PTS-2 forecourt controller has a simple and easy for integration JSON-based communication protocol and ready API and demo applications in different programming languages and platforms including Java language and Android application, C# and .NET Core application, C++, JavaScript

Practice of using the PTS-2 forecourt controller on thousands of petrol stations, storage depots and fuel delivery trucks worldwide has proved its reliability and efficiency.

FEATURES

| PARAMETER | VALUE |

|---|---|

| Connection to pumps (fuel, diesel, CNG, LPG) and register meters | |

| Maximal number of pumps connected | Up to 120 |

| Total number of pumps brands supported | 150 |

| Connection to ATG systems/consoles and probes/gauges | |

| Maximal number of ATG consoles and probes connected | Up to 20 |

| Total number of ATG consoles and probes brands supported | 50 |

| Connection to price boards | |

| Maximal number of price boards connected | Up to 5 |

| Connection to RFID/UHF readers | |

| Connection to automatic vehicle identification (AVI) systems | |

| Maximal number of readers connected | Up to 700 |

| Communication with management systems over Ethernet interface | |

| Communication with management systems over RS-485 interface | |

| Communication with management systems over RS-232 interface | |

| Encryption of communication with the management systems | |

| Number of simultaneously connected management systems | No limitation |

| Support of communication with management systems using WebSocket protocol | |

| Presence of internal database for performed pump transactions, tank measurements, in-tank deliveries, alerts, GPS records | |

| Automatic mode of control over pumps | |

| Price scheduler | |

| Presence of a built-in web-server for configuration, management, monitoring, reporting and diagnostics | |

| Users and roles management and authentication | |

| Conversion between pumps protocols | |

| Conversion between probes protocols | |

| Conversion between price boards protocols | |

| Automatic calculation of temperature-compensated volume | |

| Automatic calculation of in-tank deliveries to tanks | |

| Automatic tanks calibration | |

| Automatic leakage detection from tanks | |

| Support of GPS module for vehicles geolocation, reporting on travelled route and places of pumps fillings and changes of product levels in tanks | |

| Integration with payment solutions | |

| Integration with bank payment terminals | |

| Collection of forecourt diagnostics information for online technical support (alerts, errors, warnings) | |

| Leading internal database of tags (for fuel attendants and customers) | |

| Offline operation | |

| Built-in self-diagnostics | |

| Realtime communication to a remote server | |

| Logging of operation | |

| Remote firmware update | |

| Software Development Kit (SDK) for developers | |

| Presence of API for quick integration into third-party solutions | |

| Power supply voltage | 12 V DC |

| Current consumption | 700 mA max |

| Temperature range | from -40°C to +60°C |

| Weight | 200 g |

| Overall dimensions | 85 x 58 x 30 mm |