Technotrade changes the traditional approach to petrol stations automation: from local POS systems to IoT solutions based on the PTS-2 forecourt controller

PROBLEM

Over many decades the traditional approach to automation of the petrol stations is mostly based on the local POS system based on a PC as a central core. The technological equipment of the petrol station is connected to such a PC with the necessary POS system software: fuel dispensers, price boards, card system readers, bank terminals, card system scanners, pin pads, etc. The software of local POS systems has built-in databases of completed transactions and provides the formation of many reports necessary for monitoring the operation of the petrol station.

However, in the last years due to rapid development of Internet technologies and online communications this approach is becoming more and more excessive and too expensive. New technologies allow us to optimize the used equipment and minimize the overall cost for needed forecourt equipment and its service. The gas station automation system can be significantly simplified and made cheaper, without reducing the functionality of the system:

- we can use a cloud based POS system instead of the local POS, so the cost of each local POS system service is removed and any found problems in POS can be fixed remotely on a central server, there is no need to have a PC on each station for the POS as the cloud POS can work on any device including tablets

- receipts can be sent directly to customer's phone without a need to be printed, so the cost fo paper and service of the printers is removed

- forecourt controller can be used smarter, smaller and more cost effective, it can work 24x7 and implement most of the features, which were previously covered only by expensive and powerful POS systems, for example tank automatic calibration, integration with loyalty systems, shift management and others.

SOLUTION

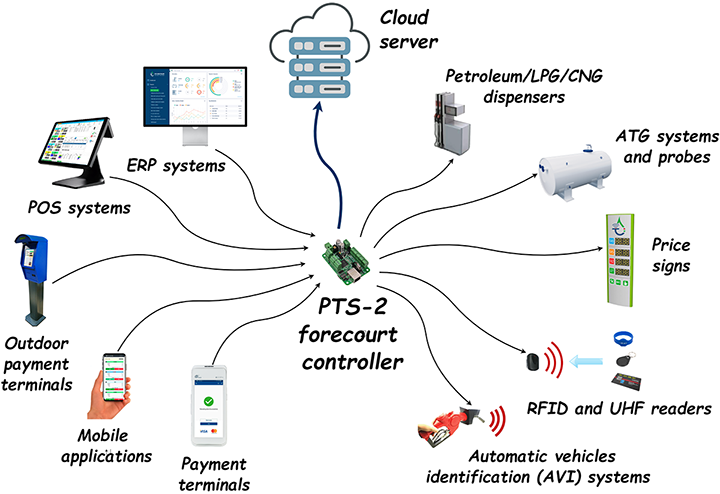

The PTS-2 forecourt controller developed by the Technotrade LLC company is a modern powerful forecourt controller with minimalistic size providing a full control over almost all forecourt equipment and allowing access to the petrol station from the cloud real-time. Application of the PTS-2 controller allows to turn the petrol station into the Internet-of-things object, allowing its full control, monitoring, reporting and configuration from remote, which is the concept of "IoT petrol station" the Technotrade LLC company is developing.

The PTS-2 forecourt controller developed by the Technotrade LLC company is a modern powerful forecourt controller with minimalistic size providing a full control over almost all forecourt equipment and allowing access to the petrol station from the cloud real-time. Application of the PTS-2 controller allows to turn the petrol station into the Internet-of-things object, allowing its full control, monitoring, reporting and configuration from remote, which is the concept of "IoT petrol station" the Technotrade LLC company is developing.

According to the proposed concept of IoT Petrol Station, any gas station can be working as an ordinary Internet-of-Thing device. Any interaction with it, any information about its operation can be obtained via the Internet remotely. The POS system of the gas station is transferred to the cloud leaving the forecourt controller to be the only device controlling all the forecourt equipment on site.

The proposed concept allows interaction with any petrol station using the the same and unified way regardless of the variety of technological equipment used on it.

The proposed concept has been implemented by Technotrade LLC company on many networks in the world.

In order to make the petrol station to become the IoT device all you need is to install the PTS-2 forecourt controller on it and connect all the forecourt equipment to it. The PTS-2 has a very rch funtionality and supports more than 200 different brands of dispensers, ATG systems and probes, price-boards, readers and AVI systems. Below are some of its technical characteristics and features.

CAPABILITIES

Here are some of the capabilities that the PTS-2 forecourt controller provides in order to turn the regular gas station into a IoT Petrol Station and several reasons why such a petrol station can be named as “smart”:

- the PTS-2 forecourt controller allows easy connection to almost any forecourt equipment: Fuel/Diesel/LPG/CNG dispensers, ATG consoles, ATG probes, price boards, RFID and UHF readers, AVI systems, leakage sensors

- the PTS-2 forecourt controller allows easy integration with cloud Internet structures of various solutions: data collection, mobile applications, payment systems solutions, ERP systems, driver identification systems, cloud Head-Offices, etc

- the PTS-2 forecourt controller allows to collect various data on a remote server depending on the need: pumps sales, tank measurements, in-tank deliveries, alerts, GPS coordinates of the route travelled, real-time monitoring, configuration, others. All data is sent in a unified way regardless of the forecourt equipment connected, and is simple in integration

- the PTS-2 forecourt controller is able to establish communication with a remote server itself without a need to have any static IP-address, VPN or Dynamic DNS services

- the PTS-2 forecourt controller provides collection of all technological alerts and warnings including tanks leakages and overfillings, pumps misoperation, equipment disconnections and failures and allows to immediately inform about any found problems to a remote server, which helps to provide the immediate required technical support keeping the low risk of station misoperation and removing the found problem within the minimal station downtime

- the PTS-2 forecourt controller provides integration with any cloud mobile applications, card solutions from various developers and other payment systems for customer service, collects a database of all transactions, provides remote visualization of reports via the web interface

- the PTS-2 forecourt controller allows you to modify the approach to the organization and meaning of the company's service department, providing it with detailed information not only about equipment failures, but also about statistical indicators of equipment operation, allows you to organize the service department at a higher level

- the PTS-2 forecourt controller simplifies the development of POS systems and systems for visualizing the operation of gas stations, since the main accounting functions (registration of receipts of petroleum products, current sales, report generation, equipment diagnostics, etc.) are already implemented in the PTS-2 controller and the POS system is only assigned the tasks of analytics and visualization

- the PTS-2 forecourt controller provides new opportunities: it can be easily "fitted" into the structure of any gas station with an existing POS system or forecourt controller, leaving the operation of the existing management system be unchanged. As a result, it can minimize the composition of equipment at the gas station, helping to move the existing POS systems to the cloud

- the PTS-2 forecourt controller provides flexibility of installation: wireless and wired ways for connecting the forecourt equipment are available. Connection of the forecourt equipment using the wireless way is done using the WFC wireless forecourt communicator

- the PTS-2 forecourt controller simplifies can track actions of the petrol station stuff, recording the sales they perform and generating reports on the activity for the management

- the PTS-2 forecourt controller provides control over possible fuel thefts at gas stations, automatically compiling a daily inventory of fuel receipts and releases during a specified period

- the PTS-2 forecourt controller provides control over leakages from tanks and pipes allowing to quickly notify about it and prevent them

- the PTS-2 forecourt controller can provides tanks automatic calibration with formation of tanks calibration tables based on actual fuel sales and in-tank deliveries, formation of daily inventory reports

- the PTS-2 forecourt controller has a simple and easy for integration JSON-based communication protocol and ready API and demo applications in different programming languages and platforms including Java language and Android application, C# and .NET Core application, C++, JavaScript

FEATURES

| PARAMETER | VALUE |

|---|---|

| Connection to pumps (fuel, diesel, CNG, LPG) and register meters | |

| Maximal number of pumps connected | Up to 120 |

| Total number of pumps brands supported | 150 |

| Connection to ATG systems/consoles and probes/gauges | |

| Maximal number of ATG consoles and probes connected | Up to 20 |

| Total number of ATG consoles and probes brands supported | 50 |

| Connection to price boards | |

| Maximal number of price boards connected | Up to 5 |

| Connection to RFID/UHF readers | |

| Connection to automatic vehicle identification (AVI) systems | |

| Maximal number of readers connected | Up to 700 |

| Communication with management systems over Ethernet interface | |

| Communication with management systems over RS-485 interface | |

| Communication with management systems over RS-232 interface | |

| Encryption of communication with the management systems | |

| Number of simultaneously connected management systems | No limitation |

| Support of communication with management systems using WebSocket protocol | |

| Presence of internal database for performed pump transactions, tank measurements, in-tank deliveries, alerts, GPS records | |

| Automatic mode of control over pumps | |

| Price scheduler | |

| Presence of a built-in web-server for configuration, management, monitoring, reporting and diagnostics | |

| Users and roles management and authentication | |

| Conversion between pumps protocols | |

| Conversion between probes protocols | |

| Conversion between price boards protocols | |

| Automatic calculation of temperature-compensated volume | |

| Automatic calculation of in-tank deliveries to tanks | |

| Automatic tanks calibration | |

| Automatic leakage detection from tanks | |

| Support of GPS module for vehicles geolocation, reporting on travelled route and places of pumps fillings and changes of product levels in tanks | |

| Integration with payment solutions | |

| Integration with bank payment terminals | |

| Collection of forecourt diagnostics information for online technical support (alerts, errors, warnings) | |

| Leading internal database of tags (for fuel attendants and customers) | |

| Offline operation | |

| Built-in self-diagnostics | |

| Realtime communication to a remote server | |

| Logging of operation | |

| Remote firmware update | |

| Software Development Kit (SDK) for developers | |

| Presence of API for quick integration into third-party solutions | |

| Power supply voltage | 12 V DC |

| Current consumption | 700 mA max |

| Temperature range | from -40°C to +60°C |

| Weight | 200 g |

| Overall dimensions | 85 x 58 x 30 mm |

Products in structure of this solution:

|

PTS Monitor server software

The PTS Monitor server is designed for collecting reporting and real-time data from the PTS-2 forecourt controllers and other necessary information about the operation of the forecourt equipment of the gas station network, where the PTS-2 forecourt controllers are used for control over equipment.

|

PTS Pay forecourt application

PTS Pay mobile application is a forecourt control application, which allows fuel station’s customers to pay for fuel at the dispenser or even without leaving their vehicle. The application allows attendant and unattended modes of control over fuel dispensers, payment for performed pump transactions.