SIUR console for petrol stations and storage depots

SIUR tank monitoring system for petrol stations and storage depots is appointed for:

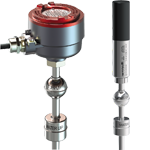

- monitoring existing remains of fuel and its parameters in tanks of petrol stations and petroleum storage depots using ATG systems and probes of different manufacturers

- monitoring and control over dispensers and risers at petrol stations and petroleum storage depots

- temperature correction of fuel volume and compensation to 15 degrees Celcium

- transmission of reports to remote server and email notification

Operation #

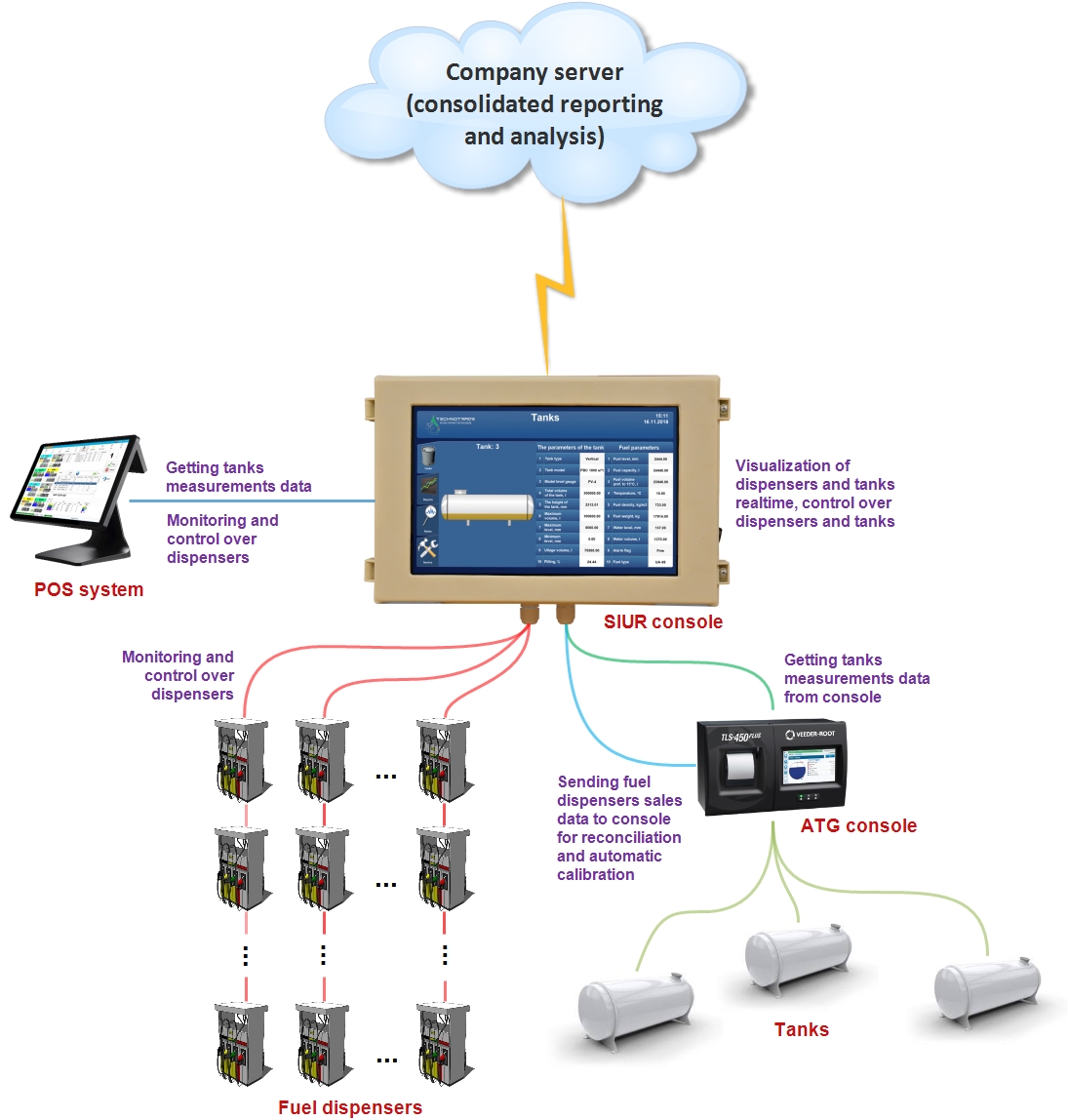

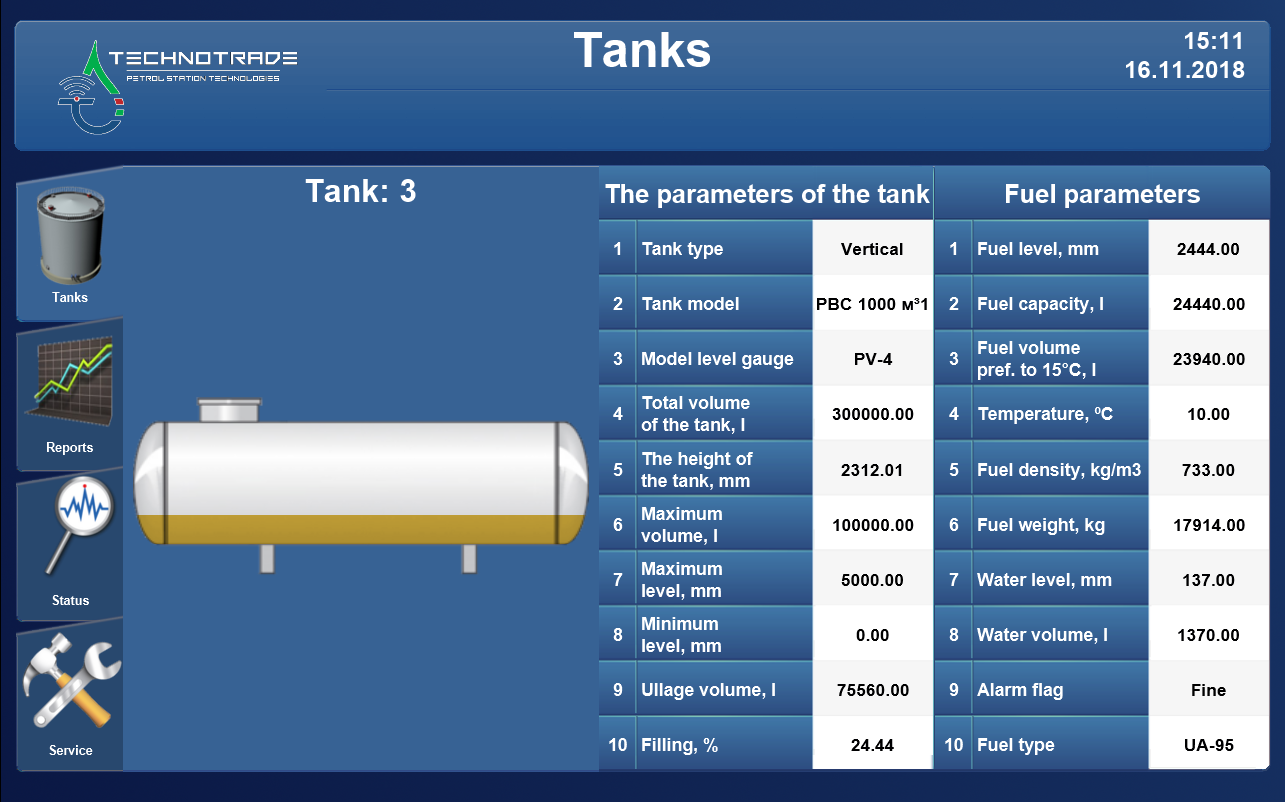

SIUR console is to be connected to the ATG system or probes and provides visualization and storing of the tank parameters. Information on product/water volume can be taken directly from used ATG system, SIUR console can also provide calculation of volume based on product/water level, for this tanks’ calibration charts should be input in the SIUR console.

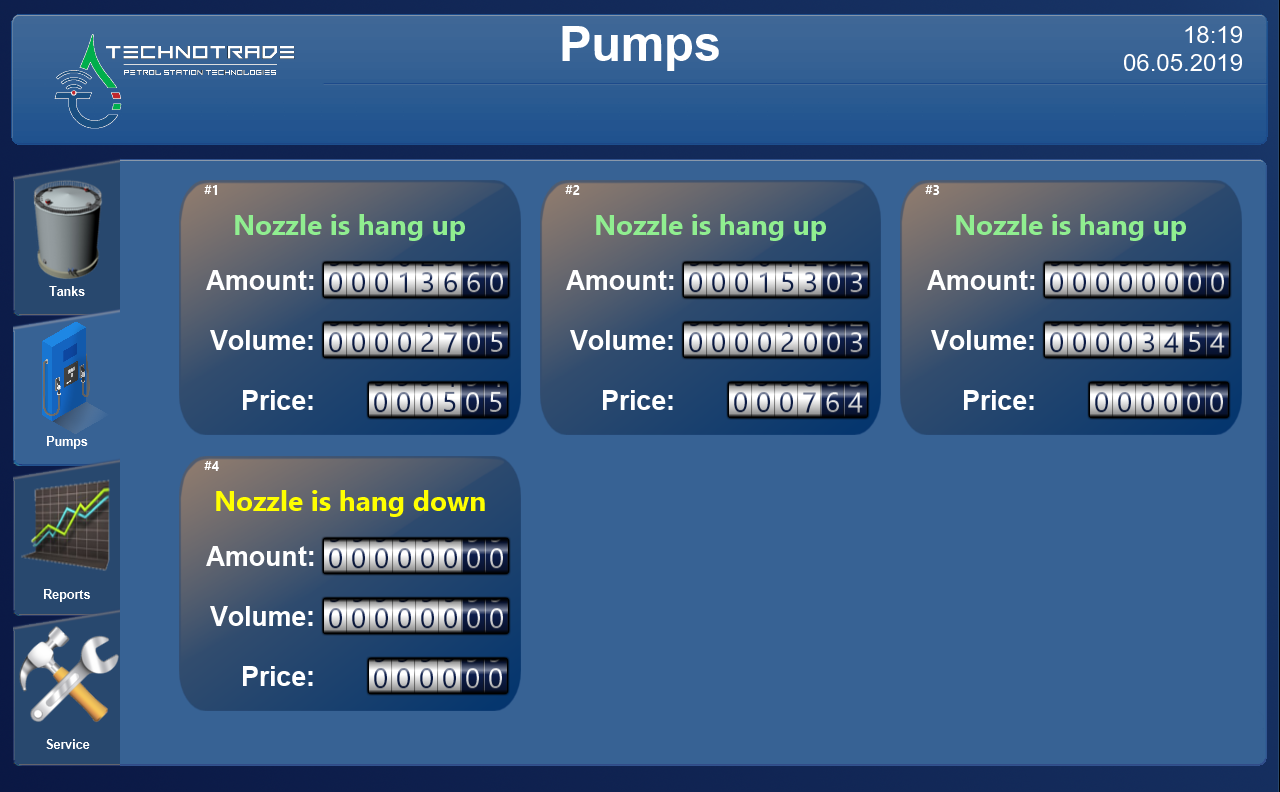

SIUR console allows to monitor operation of the fuel dispensers and tanks (and optionally to make sales when required) together with existing POS system installed on the station. At this SIUR console allows to view information about each dispenser sales and each tank realtime state and remains, to generate reports and send all data to the central server.

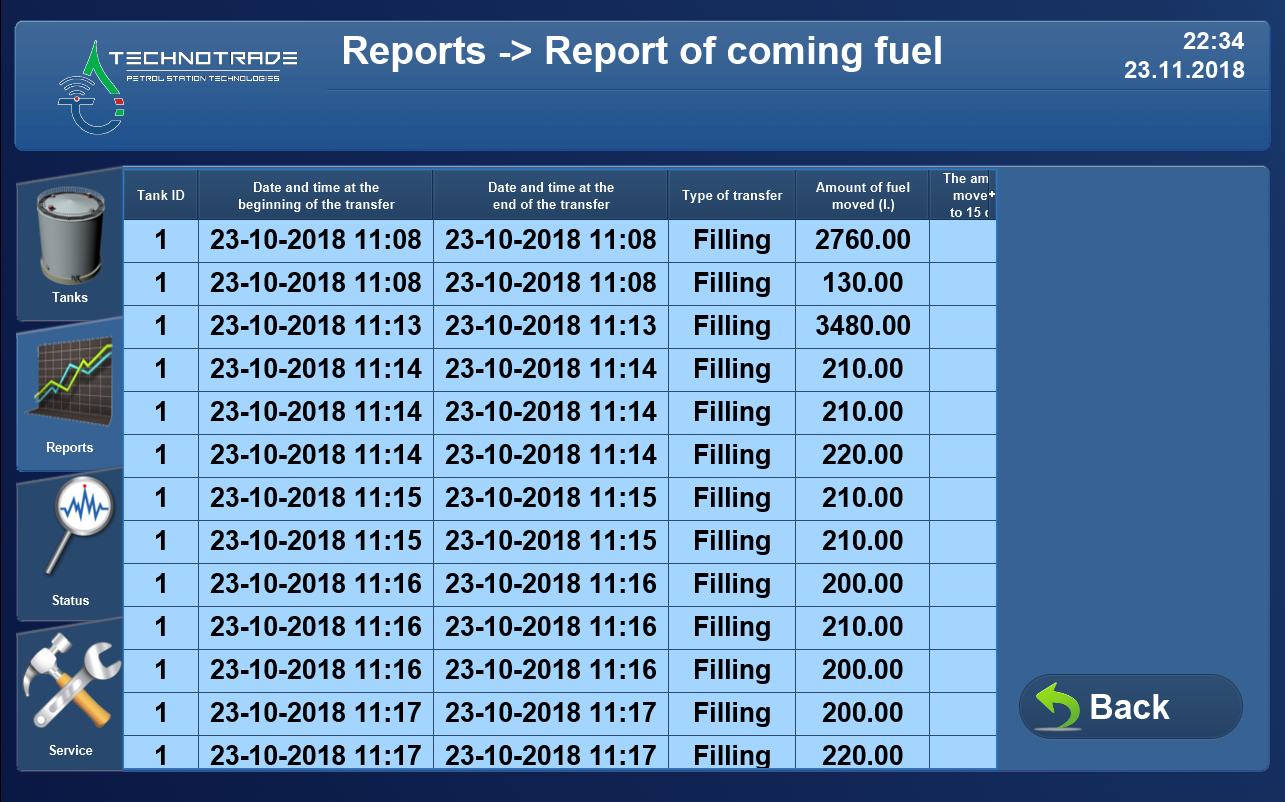

SIUR console has built-in reports and charts, there are many parameters for flexible adjustments.

SIUR console automatically detects in-tank deliveries, report for in-tank deliveries can be generated.

SIUR console can be configured for automatic sending of reports to remote server for formation of consolidated reports on several petrol stations or petroleum depots.

Functions #

- Communication with ATG systems and probes and visualization of measurement values on the display online

- Monitoring and control over fuel dispensers and risers and visualization of values on the display online

- Provision of tank calibration charts and calculation of volume based on tanks calibration charts

- Automatic registration of in-tank deliveries and expenditures

- Automatic registration of in-tank product temperature changes

- Possibility of manual input of temperature-compensated volume of product reduced to 15°C

- Generation of reports and charts

- Automatic sending of reports to a remote server for formation of consolidated reports from several petrol stations or storage depots

- Automatic sending of reports in a view of emails

- Signaling at emergency

- Remote firmware update

Technical characteristics #

| PARAMETER | VALUE |

|---|---|

| Maximal number of connected tanks | up to 50 in extended version |

| Maximal number of connected fuel dispensers and risers | up to 50 in extended version |

| Interfaces for communication with ATG systems and probes | 1 x RS-485, 3 x RS-232 |

| Interfaces for communication with fuel dispensers and risers | 4 x RS-485 (for fuel dispensers with different interfaces connection is done through dispenser interface converters) |

| Display | IPS display 10.1 ″ with capacitive touchscreen |

| Power supply voltage | 220 V AC |

| Current consumption | 1 A max |

| Temperature range | -20°C ÷ +60°C |

| Protection class | IP54 |

| Weight | up to 2 kg |

| Overall dimensions | 315 x 215 x 85 mm |

Supported probes and ATG systems communication protocols #

Supported pumps communication protocols #

Need more protocols?

We are constantly expanding a list of supported communication protocols and forecourt equipment.

Please contact us if you are interested in other pumps or probes brands, communication protocols or control equipment not listed here.