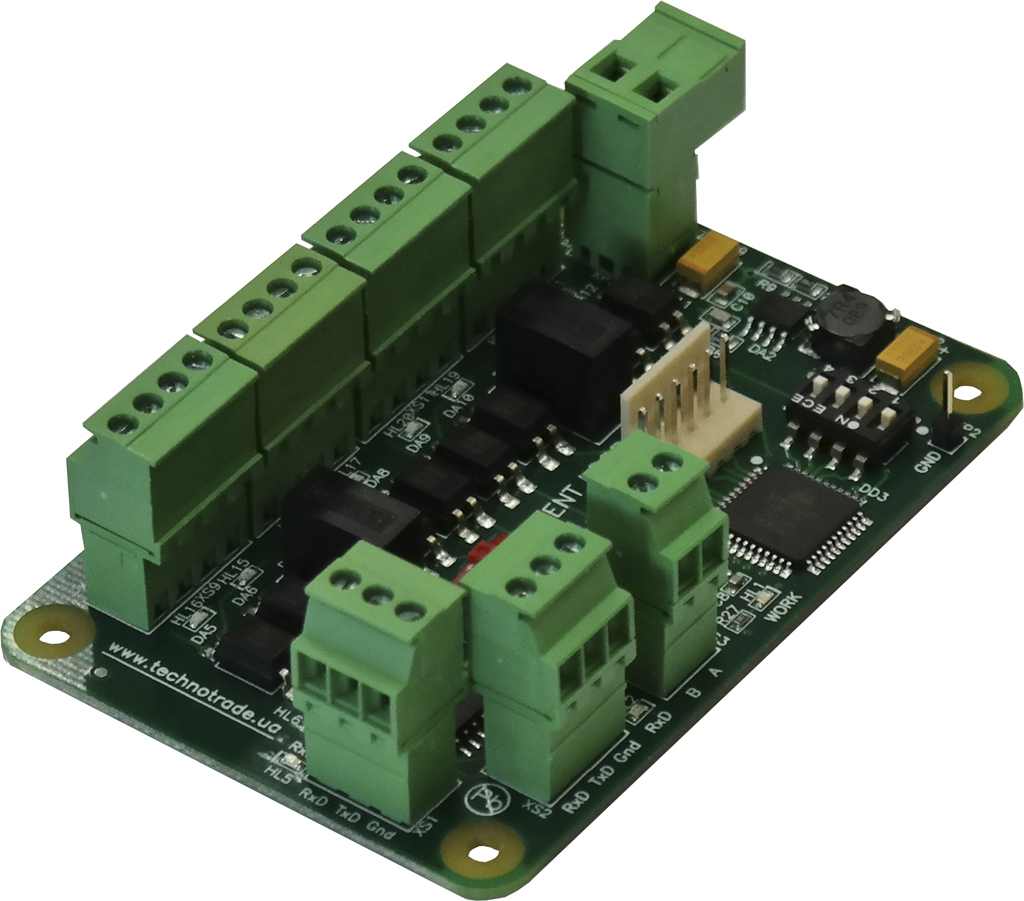

HY dispenser interface converter

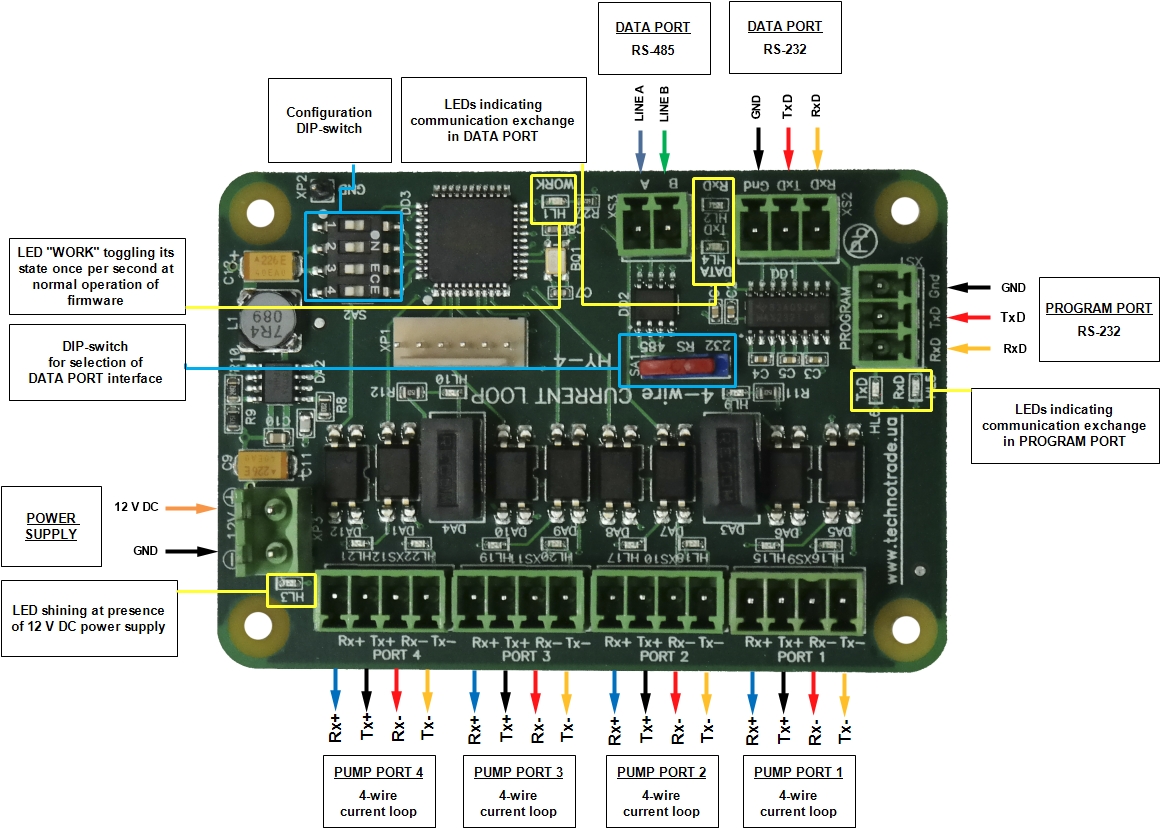

HY interface converter (RS-485/RS-232 to 4-wire current loop and backwards) is intended for communication with fuel dispensers, which use 4-wire current loop interface, through interfaces:

- RS-232,

- RS-485 (2 wires)

Technical characteristics #

| PARAMETER | VALUE |

|---|---|

| Power supply voltage | 12 V DC |

| Current consumption | 150 mA max |

| Power supply in current loop interface | Galvanically isolated |

| Temperature range | from -40°C to +80°C |

| Weight | 100 g |

| Overall dimensions | 85 x 58 x 30 mm |

Frequently asked questions #

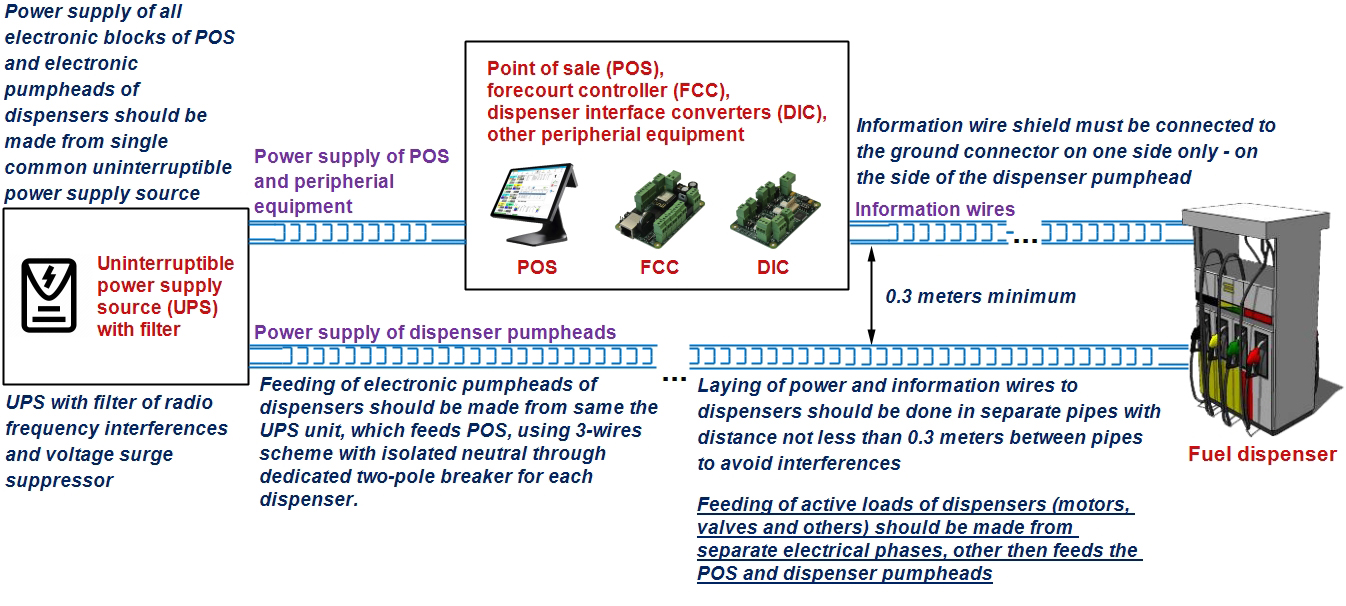

WARNING! Manufacturer guarantees reliable and stable operation of products only at compliance with below requirements. In case of absence of uninterruptible power supply or incorrect wiring of products to it any claims to malfunction of software are not accepted.

1. Requirements to power supply

The described products come into structure of control system (POS) for petrol station. Power supply of the products should be done from a separate power supply with built-in filter of radio frequency interferences and limiter of high voltage pulse interferences. Power supply should have a safety factor of 1.5.

At emergency switching off the power supply or in case of power voltage exceeding its permitted ranges the products can switch off with loss or corruption of data and possible damage of hardware and software. Power supply of all electronic blocks of POS and electronic pumpheads of dispensers, which are connected through information lines, should be made from single common uninterruptible power supply source (UPS). Connection of other devices to given UPS is strictly prohibited. UPS should be of continuous action (online) and work with double conversion with output voltage regulation. UPS should have a safety factor of 1.5. Filter of radio frequency interferences and limiter of high voltage pulse interferences should be used for feeding equipment from UPS.

Supply of electronic pumpheads of dispensers should be made from the UPS unit using 3-wires scheme with isolated neutral through dedicated two-pole breaker for each dispenser. Connection of other parts of dispenser to UPS unit (expect electronic pumpheads) is strictly prohibited.

UPS unit should be connected to a separate three-pole socket fed through the three-wire feeder (phase, neutral, ground wires) with insulated neutral from a dedicated circuit breaker of switchboard. Feeder coming from the switchboard to the socket should located not closer than 0.3 meters to other feeders. The socket should be located at a distance of not more than 1 meter away from the POS. Phase wire of the feeder should not have any other consumer, which are sources of interferences (for example motors).

For protection of POS and UPS from secondary effects of atmospheric electricity it is required to install high-voltage arresters (dischargers) at the transformer substation or on poles of power lines.

2. Requirements to grounding

In the switchboard the ground wire of feeder socket should be connected to the grounding screw, which should be connected by means of welding with a protection grounding circuit of petrol station by steel wire with a diameter of not less than 5 mm.

Protection grounding circuit of petrol station should correspond to safety requirements and be separated from the station lightning protection circuit. Distance from the nearest electrode of protection grounding circuit to electrode of lightning protection circuit must be at least 10 meters. Resistance of the protection grounding circuit should be not more than 4 Ohms and must be confirmed by the test report. Length of wires from the switchboard to the nearest electrode of protection grounding circuit should not exceed 15 meters.

3. Requirements to laying of cable communications

Laying of power and information wires to dispensers should be done in separate pipes with distance of not less than 0.3 meters between each other. For informational wires (current loops, RS-485, other interfaces) it is recommended to use shielded twisted-pair cables (recommended type – FTP CAT 5E). The cable shield must be connected to the ground connector on one side only – on the side of the dispenser.

Yes, HY interface converter has 2 interfaces for communication with a control system: RS-232 (3 wires: TxD, RxD, Gnd) and RS-485 (2 wires). Thus using RS-232 interface you can connect HY interface converter to COM-port of personal computer.

As the HY interface converter has several pump channels and can be connected to several pumps (2 channels or 8 channels depending on the board type HY-2 or HY-8) it is better to install it near the control system. 4-wire current loop communication interface, through which it connects to dispensers can have a cable length up to 1200 meters. If the converter is connected to control system through the RS-232 interface - then normally the cable length between the control system and converter should not exceed 15 meters to guarantee normal operation. If the converter is connected to control system through the RS-485 interface - then cable length between the control system and converter can be up to 1200 meters.

HY interface converter is supplied without cables for connection to dispensers. For connection to dispensers you will have to prepare the cablings yourself. You can use any standard FTP cable with twisted pair and aliminium foil for screening (like FTP CAT 5E) for connection.

HY interface converter uses 12 V DC for feeding. Maximum current consumption is 75 mA for HY-2 converter type and 350 mA for HY-8 converter type.

Power supply source is not supplied together with a HY interface converter. The power supply should be selected locally. This is connected with a reason that different countries may have different electricity network specifics: frequency and voltage.

At selection of the power supply you need to pay attention to the following 2 factors:

- output voltage of power supply should be 12 V DC

- maximum allowed current consumption of power supply should be more that maximum current consumption of the converter. If several devices are connected to the same power source - then their total current consumption should be less than maximum allowed current consumption of power supply.

Connection schemes of the HY interface converter to dispensers are shown in HY interface converter technical guide, which you can download 'Downloads' section of the HY interface converter web-page.

HY interface converter does not have a communication protocol. It serves for conversion of the interface and improve transmission between the control system and dispensers.

Order information #

Ask YOUR questions about

"HY dispenser interface converter"

Other products of section:

|

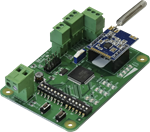

Wireless forecourt communicator WFC

Wireless forecourt communicator WFC allows communication with any brand of dispensers (fuel, LPG, CNG), tank probes and consoles, price poles in a wireless way without a need to put any cables. WFC has a rich set of electric interfaces on board (RS-485, RS-232, 2/3/4-wire current loops, voltage)

|

NA dispenser interface converter

NA interface converter (RS-485/RS-232 to non-addressable RS-422/RS-485/RS-232 and backwards) is intended for communication with fuel dispensers, which do not have a communication address in communication protocol and use one of the interfaces RS-422, RS-232 or RS-485 through interfaces:

|

Wireless interface converter RFC

Wireless interface converter RFC for petrol stations is appointed for establishing of wireless communication between devices having interfaces RS-232 and RS-485. RFC converter does not bring any changes to exchanged data between devices. Thus, RFC interface converter is a complete anal